TECHNICAL DATA

ALUMINUM AIR LINE SALES IN ARKANSAS

Infinity Pipe Systems high-performance compressed air pipe & airline fittings, are compatible with compressed air, nitrogen and vacuum systems. Extend, connect, and easily install compressed air systems by selecting from an expansive range of compatible Infinity Pipe Systems quick connection air pipe & airline fitting accessories.

Infinity Technical Data

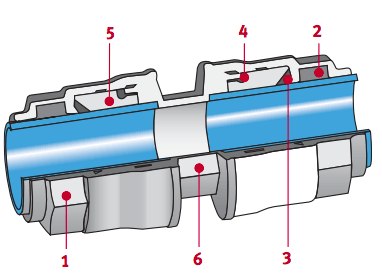

COMPONENT PARTS AND MATERIALS

1. Nut: Nickel Plated Brass

2. Seal:

High Nitrile

3. Clamping Washer:

Inox AISI 304

4. O-Ring Seal:

Made of NBR

5. Safety Ring:

Technopolymeric

6. Body:

Nickel-Plated Brass

| Temperature | Minimum: -4°F (-20°C) Maximum: 176°F (80°C) |

| Pressure | Minimum: -0.99 bar (-29.6Hg) Maximum: 15 bar (220 psi) |

| Fire Resistance | System does not stroke or propagate fires |

| Compatibility | Compressed Air, Vacuum, Inert Gases |

| Male Threads | Taper in Conformity with ISO |

| Female Threads | In Conformity with ISO 228 |

Tubing Technical Data

| 20mm | 25mm | 32mm | 40mm | 50mm | 63mm | |

|---|---|---|---|---|---|---|

| (3/4") | (1") | (1-1/4") | (1-1/2") | (2") | (2-1/2") | |

| Weight: lbs/ft | 0.159 | 0.202 | 0.262 | 0.331 | 0.592 | 0.623 |

| Pressure: Bar/psi | 15/220 | 15/220 | 15/220 | 15/220 | 15/220 | 15/220 |

| Tubing Length | 16ft | 16ft | 16ft | 16ft | 16ft | 16ft |

| Extruded Aluminum: | Aluminum 6063/ AA6063-T5 |

| Chemical Composition: | Si: 0.2--0.6 - Mg: 0.45 ÷ 0.9 - Fe: 0.35 |

| Designations: | AA 6063 Alloy |

| Heat Treatment: | Thermal Heat Treat "T5" |

| Surface Treatment: | Electrostatic Painting |

| Density: | 2.7 g/cc - 0.0975 ib/in3 |

| Electrical Resistivity at 68°F: | 19 ohm-Cir. Mil/Foot |

| Thermal Conductivity at 77°F: | 209 W/m-K -1450 BTU-in/hr |

| Expansion Coefficient (Avg @ 68° to 212°F per °F): | 13 |

| Heat Capacity: | 0.9J/g- °C / 0.215 BTU-in/hr-ft2 |

| Ultimate Tensile Strength: | 21.0 ksi / 21,000 psi |

| Modulus of Elasticity: | 68.9GPa / 10,000 ksi |

| Tensile Strength: | 15.0 ksi min / 15,000 psi |

| Brinell Hardness: | 60 ÷ 70 HB |

| Melting Point: | 615°C to 650°C / 1140-1210°F |

| Percentage Elongation: | 8% |